LEO M-1

Produce 350 KN thrust

LEO M-1

LEO M1 is a dedicated small satellite launch vehicle engineered by SPACIM, designed to deliver payloads ranging from 100 kg to 1,500 kg into Low Earth Orbit (LEO). With an operational altitude range spanning 200 km to 1,200 km, LEO M1 is optimized for diverse mission profiles, including Earth observation, communication constellations, and scientific payloads.

The vehicle features a two-stage architecture, employing a streamlined system design to ensure enhanced reliability, improved performance, and simplified operations. LEO M1 is built with modular adaptability, allowing mission-specific configurations to meet the precise requirements of commercial, academic, and governmental payloads. By integrating advanced manufacturing techniques and efficient design principles, LEO M1 is poised to offer cost-effective and high-performance launch solutions for the evolving space market.

LEO M-1

OVERVIEW

Diameter

Length

Payload to LEO

Lift-Off Thrust

1.5 m

25 m

100 kg to 1500 kg

350 KN

The first stage is propelled by seven Rudram engines that use green propellants. First stage, produce 350 KN of thrust at sea level.

The interstage has a pneumatic system that separates the first and second stages during flight.

One vacuum-modified RUDRAM M-1 is used in the second stage. Second stage supports putting the payload in the desired orbit.

Our specially designed payload compartment is an adjustable one that can accommodate various payload geometries. The basic dimensions of our payload compartment are 1.3 metres in diameter and 3 metres in height.

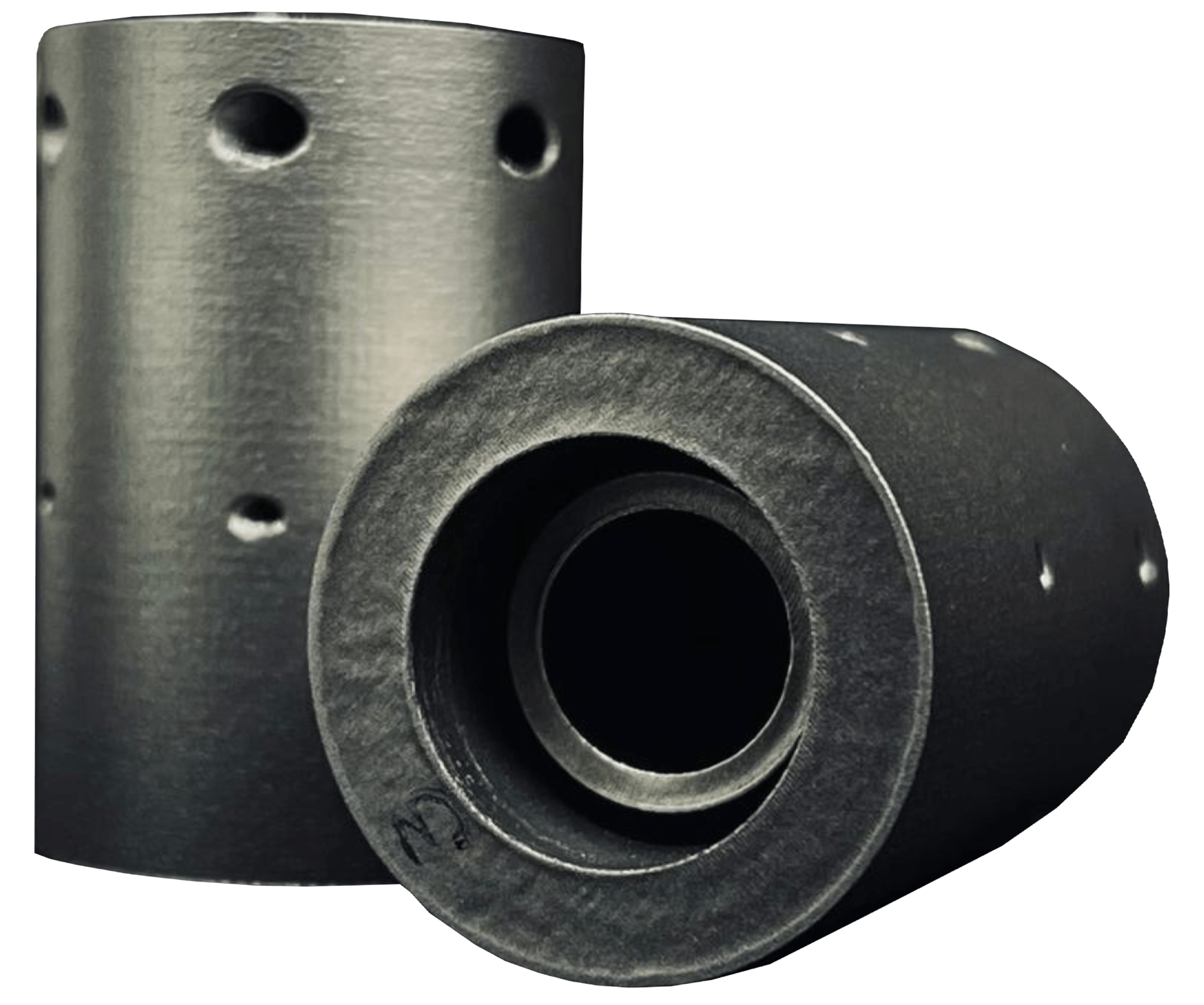

RUDRAM M-1

Developing the single piece liquid rocket engine with a more straightforward design and cutting-edge materials.

RUDRAM is a particular kind of liquid rocket engine that aims to be highly powerful and reusable.

Composite materials are used often in the aerospace sectors nowadays. To increase the thermal stability of the wall of engine components and to achieve the reusability of the engine, we are developing the simplified design of the liquid engine and also researching the advanced materials for the wall of the combustion chamber and nozzle of the engine. A mathematical model is being developed.

RUDRAM is incorporated with our specially designed liquid propellant injector called, SPIM Injector-Variant 1.

The most important and foundational initiative for Spacim is Project – RUDRAM.

Single-Piece Internal Mixing Injector (SPIM) Variant 1

A Single-Piece Internal Mixing Injector is a fully 3D printed injector that does not require any post machining processes. It is a single-piece component that may be incorporated into any engine.

Spacim designed this injector with the idea that it may be expanded to accommodate different mass flow rates.

One of the primary advantages of this injector is that it has no support structures. This allows this injector to be lighter in weight than a conventional injector with the same configuration, as well as have a far less production cost and time.

Co-Axial Swirl Injectors

A fully 3D-printed internal mixing coaxial swirl injector made of Inconel alloy.

- Co-Axial Swirl Injector – Internal Mixing

- Single Piece Injector Assembly

- No Support Structures

- 50 µm Size of Droplets

- 99.9% Mixing Efficiency